A True American Manufacturer

We have been manufacturing window shades in Spiceland, Indiana since 1902. Over 700 employees design, engineer, and build our products right here. Most live within 30 minutes of our facility

How Draper Supports Your Mission

We bring more to the table than just price or compliance checkboxes. We offer trusted American manufacturing, long-term partnership, and peace of mind.

American Partnerships

We work with U.S.-based fabric mills Phifer and Mermet®, who proudly offer Made-in-USA shade fabrics. These partnerships provide us with improved supply chain control and help protect you—and us—from turbulent tariffs.

What this means to you

- Stability: Family-owned, financially sound, and committed long-term.

- Speed: No overseas delays—everything ships from Indiana, with typical lead times of 8-10 days.

- Service: We prioritize relationships over transactions.

- Standards: Full control over quality and performance.

- Sustainability: Local production and on-site solar generation.

- Value: A responsive partner with technical expertise and manufacturing integrity you can count on.

Historic Choices Benefit Partners

We are not a transactional company, looking to race to the lowest bottom line. We base our business on long term partnerships and deeper relationships for better outcomes. We have complete control over the manufacturing process. Multiple quality checks throughout the process, and final inspection of the completed product, reduce errors and returns.

Draper is a debt-free, financially-sound, family-owned company. Draper is not going anywhere; the company will never be sold and is not dependent on nor beholden to a larger entity. As an American manufacturer, our pricing is also more stable - tariffs have much less of an impact on us.

All of these add up to stability, a focus on customer service, fast, reliable delivery, and the knowledge that whenever you need us - next week, next month, next year, or next decade - Draper will be here for you.

Our Core Values

These values define who we are and how we work—every product, every partnership, every day.

Solid

We build on our strong foundation to provide stability for future generations.

We are a family-owned business built on integrity.

We strive to create a caring, supportive, and safe environment.

We work together to overcome challenges.

Partnership

We commit to building strong connections with our customers, employees, and community.

We will respectfully balance the needs of partners and customers to maintain mutually beneficial relationships.

We weigh community and employee best interests when making key business decisions.

Growth

We seek, explore, and leverage opportunities to grow our employees.

We empower our employees to learn and adapt through our shared experiences.

We invest in our people and actively promote their development.

Strategy

We draw from deep expertise to continuously improve and hold ourselves to a standard of excellence.

We actively seek the next opportunity to drive growth and innovation.

We develop creative products and solutions to meet our customers' needs.

Integrity

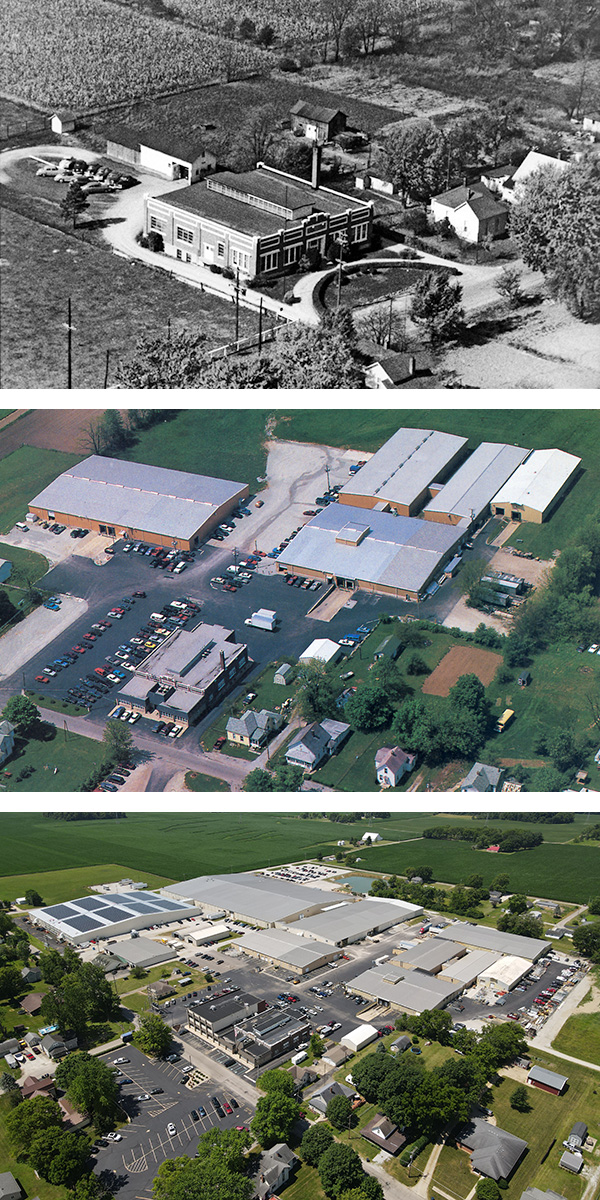

Draper circa 1950s, 1990s and today

Draper circa 1950s, 1990s and today

We’ve called Spiceland, Indiana home for more than a century, and that commitment and investment in the community makes us who we are. While many of our competitors have moved production to other countries, our commitment to and investment in our local community remains strong.

Draper has never laid off any employees. Our employees enjoy competitive wages and a growing benefit package, profit sharing and a 401(k) plan with matching contributions. Draper also provides a generous group medical plan that includes an innovative free on-site primary care medical clinic and an award-winning wellness program.

Draper supports the local community. The company supports many causes that are important to our employees, including the public library, volunteer fire department, community center, school corporation, and youth organizations. Draper generously and consistently supports the volunteer and community activities of its employees.

What this means to you.

You need to be confident that your solution will work. Every product we make is tested before it leaves the factory to make sure it’s right. We test each batch of screen material to make sure it meets our published specifications. If it doesn’t, we don’t sell it. And if a product that doesn’t meet our specification does somehow happen to get out, we make it right as quickly as possible.

Why Draper?

You can choose from many manufacturers. Here's why you should partner with us.

Family connections are important to the Draper business model. More often than not, a family-owned business succeeds in having closer relationships with customers because it’s more than just a business. It’s a legacy. And it’s a legacy that pays off for our partners:

- Better lead times

- Higher profitability and more capital to invest in people, technology, and product advancements

- Better pricing for our customers

- Continuity of management

Creating partnerships...

Partnerships are the heart and soul of the Draper business model. We partner with other U.S.-based manufacturers, architects, dealers, installers, end users and suppliers to make sure you and your customers have the best possible experience.

...designing and manufacturing innovative products...

Draper has the capability and capacity to deliver a solution that matches your unique needs, from the simplest of jobs to the most complex challenges.

We use lean manufacturing processes to keep ahead of changing needs and markets. We continually measure and improve our processes by eliminating waste and balancing work between our production employees.

...with integrity...

We’ve called Spiceland, Indiana home for more than a century, and that commitment to the community makes us who we are.

What this means to you: You need to be confident that your solution will work. Every product we make is tested before it leaves the factory to make sure it’s right. We test each batch of screen material to make sure it meets our published specifications. If it doesn’t, we don’t sell it. And if a product that doesn’t meet our specification does somehow happen to get out, we make it right as quickly as possible.

...as we have since 1902.

Longevity and stability are important factors when choosing manufacturing partners. You can’t afford to specify a company’s product only to see them go out of business.

Draper is currently into our fifth generation of family ownership and leadership. That kind of longevity shows we will be around when you need us. It also shows we have a successful record and a knowledgeable workforce ready to meet the needs of the future.

Sustainable Manufacturing

You might say we’ve been in the sustainability and energy efficiency business since 1902. Window shades reflect light and heat from the sun, reducing the amount of energy required to cool the building. The construction of Draper products has become friendlier to the environment by including increasing quantities of low- and zero-emission materials and increasingly efficient manufacturing processes.

Draper continually promotes sustainability in our manufacturing processes and the materials we use. We recognize the importance of materials reporting and provide Health Product Declarations and/or Environmental Product Declarations for many of our components.

Draper's new building with solar panels

Draper's new building with solar panels

Draper utilizes an energy monitoring and control system to shut down or reduce building systems in areas where they are not in use – including lights, air compressors, and HVAC.

We have highly efficient motion-sensitive LED lighting through most of our factory so that unoccupied areas do not draw power.

Draper recently installed solar panels which will reduce the amount of outside electricity purchased by 40%.

We have greatly reduced the amount of scrap we produce, and much scrap we have is recycled or reused. For example, we collect the cores on which shade fabrics are rolled, and return them for reuse. We also return some shade material scrap for recycling, and we reuse shipping pallets and skids.

How to Recycle our Products

Draper accepts end-of-life Draper products back for recycling. However, the sender is responsible for all shipping costs.

It is much more sustainable for you to recycle locally:

- Saves shipping costs

- Lessens transportation carbon load

- Make some extra cash

To prepare a product for recycling, separate shade fabrics or viewing surfaces from the metal parts of the unit. If there are any packaging materials remaining from when the product was installed, make sure they are recyclable before placing into any mixed recycling drop.

Recycling Tips:

- All metal parts are normally acceptable in mixed recycling drops.

- Separate aluminum, steel, and motor parts if using a metal recycler. Metal recyclers will pay for these items, and at a higher rate if you recycle in large quantities and separate by type.

- Use a magnet to distinguish steel from aluminum.

- Shade and screen motors contain steel and copper, or an electronics recycler in your area may accept motors (see link below).

- Unsupported vinyl viewing surfaces and vinyl shade fabrics are accepted by many vinyl recyclers (see link below). Relatively few recyclers accept vinyl with a woven base or backing.

Some materials may be repurposed. For instance, vinyl screen surfaces with a woven backing work well as tarps or drop cloths, so local contractors or your own installation crew may be able to reuse them. If the product being replaced is still in usable condition, donate it to a local organization, or to a local thrift store. Reuse is the most efficient form of recycling, and your donation may be tax deductible!

Below are links to help you find places to donate or recycle Draper products.

Recycling Locations and Resources

Donation Resources